REPURPOSING POTENTIAL OF HOUSEHOLD WASTES

0

%+

YEARS TEAM EXPERIENCE

0

+

REPURPOSING POTENTIAL OF IN-SITU LANDFILL WASTES

0

%+

Introducing the new Global Benchmark for turning Waste into Power by Continuum Energy.

Are you looking for a new green technology in the sustainable energy and circular economy spaces to invigorate and power your world?

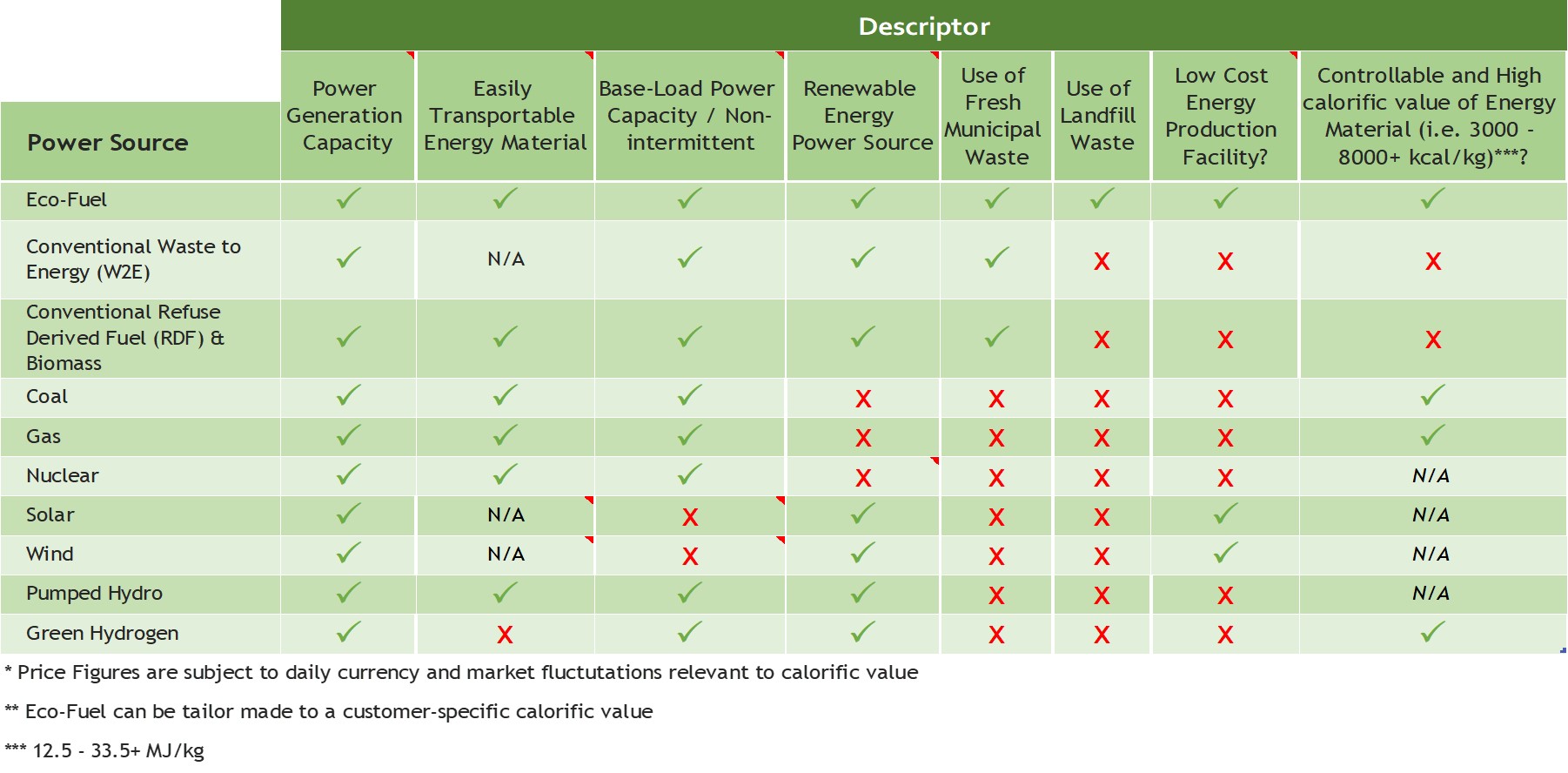

Whether it’s transforming your business’s waste materials into an eco-friendly power supply or into new commercial materials, look no further than Eco-Fuel, the revolutionary new cutting-edge renewable fuel product developed by Continuum Energy. Made from a wide variety of waste materials, Eco-Fuel is a clean, efficient, and cost-effective alternative to traditional fossil fuels and the new player in the green energy, resource recovery and circular economy spaces!

Our Eco-Fuel solution is designed to be environmentally friendly, sustainable and cost-effective for all stakeholders ranging from the feedstock supplier to the off-taker and everyone else in between! Made from a wide variety of waste materials, Eco-Fuel is a clean, efficient and cost-effective alternative to traditional fossil fuels and sets a new global benchmark to change the way we fuel our world and utilise waste materials in circular economy frameworks.

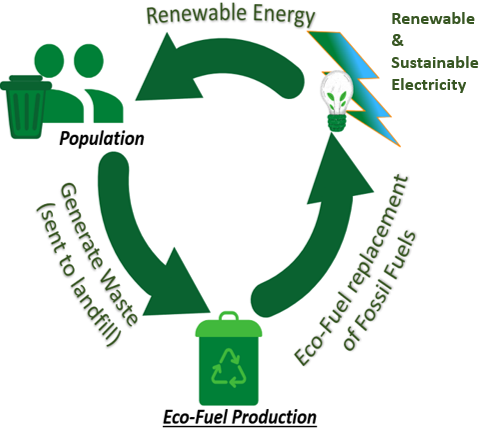

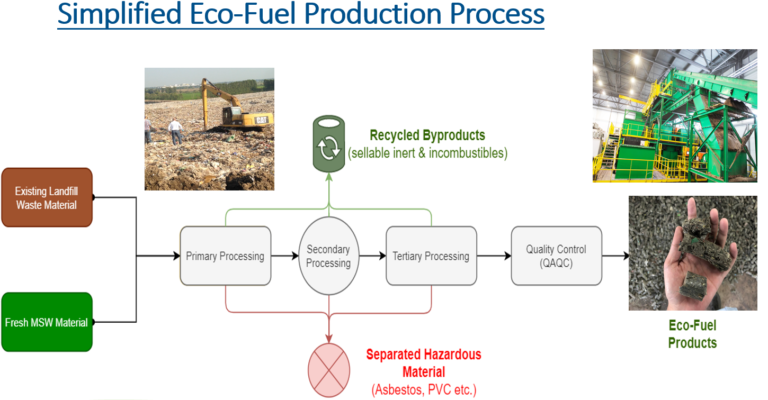

Eco-Fuel is an innovative and environmentally friendly product that is made from a wide variety of waste materials, including municipal solid wastes (MSW), industrial wastes and agricultural wastes from businesses, households and even landfills. The waste materials are processed and converted into high-quality fuel pellets, briquettes or shreds which can be used in for green power generation. As long as there are humans there will be waste materials, an infinite and constant stream of feedstock to make Eco-Fuel; proving the path to a renewable future whilst simultaneously reducing humanity’s landfill footprint.

Legacy refuse waste or a landfill over 8 years is an ideal source for the development of our Eco-Fuel solution.

Old rubbish sites can be remediated by removing the existing below ground rubbish/ waste from the site and putting it through our process to produce Eco-Fuel.

Recycled materials and other industrial by-products can be made into Eco-Concrete or used in other sustainable solutions.

By excavating (mining) existing landfill sites we hope to focus the world's attention on the significant role of Eco-Fuel production will have in the waste to energy and circular economy sectors. We believe in our capability to assist private industry, government authorities, councils and landowners alike in meeting their environmental and sustainability goals. Unlike other waste management companies, Continuum Energy brings a new concept and reimagines the Waste Management and Energy business sectors as one. We not only manage the handling of the daily fresh general and municipal waste but also take care of the below ground, old waste on existing landfill sites.

Eco-Fuel has become feasible due to Continuum’s specialised process which can turn waste materials, including those from in-situ landfill, into Eco-Fuel that can provide base load renewable power. Continuum Energy has the process know-how and technology, plant specification, engineering design and management knowledge to assist in the remediation of legacy landfill sites and/or diversion of household and municipal solid wastes (MSWs) for the production of Eco-Fuel.

Continuum’s Eco-Fuel solution is playing its part in the world’s waste management strategy and sets a new global benchmark to change the way we fuel our world. The Eco-Fuel process has become feasible due to Continuum’s specialised process, turning landfill into Eco-Fuel that can provide base load renewable power.

Continuum Energy has the process know-how and technology, plant specification, engineering design and management knowledge to assist in the remediation of legacy landfill sites.

Various landfill or municipal solid waste components can be processed for Eco-Fuel. Such components include plastics, paper, cardboard, labels, rubber, textiles, and all other combustible materials.

Non-combustible materials, such as aggregates, metals and glass (etc.) which is unsuitable for Eco-Fuel can still be processed and separated for direct separation and recycling to truly ensure a green circular economy with as many wastes in circulation as possible.

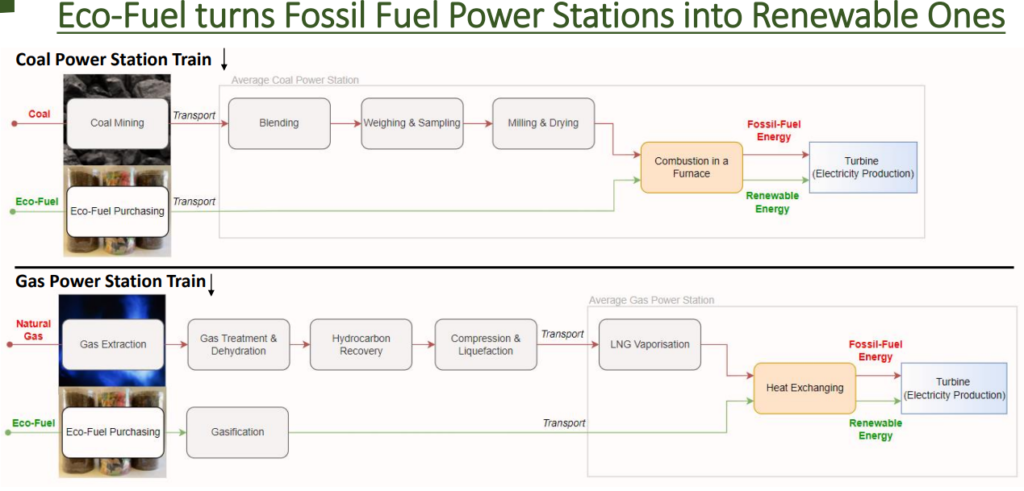

The main use for Eco-Fuel is in combined heat and power facilities, producing hot water and electricity for municipal heating systems. However, Eco-Fuel can also be used for a range of other purposes, such as for cement kilns, plasma arc gasification modules and in pyrolysis plants (etc.).

Eco-Fuel helps to divert waste away from landfill. Materials such as non-recyclable plastics, which would sit in landfill sites for hundreds of years, can instead be used in a helpful way to generate renewable heat and power. This makes Eco-Fuel a great option for companies who are seeking to be sustainable and eco-friendly. It can be used alongside various other measures to help you achieve zero waste to landfill and has the ability to transition fossil fuel power stations into renewable power stations by changing their fuel source.

Eco-Fuel can be produced and supplied at a design calorific value specified by the customer in coarse or fine shredded form and/or compacted or baled for transport as briquettes or pellets (etc.), depending on the end user’s requirement and location.

• Eco-Fuel helps to divert waste away from landfill and is an environmentally friendly alternative to traditional fossil fuels; being used either as a fossil fuel partial substitute or complete replacement. This makes businesses using Eco-Fuel for power or providing waste material feedstocks for Eco-Fuel production eco-friendlier whilst still meeting their sustainability, financial and/or electricity needs in a cost-effective way.

• Using Eco-Fuel in your business can help companies and individuals meet their sustainability goals and targets. It can be used alongside various other measures to help ensure your business achieves zero waste to landfill status, reduced greenhouse gas (GHG) emissions for a better carbon footprint and/or carbon credit benefits (just to name a few!).

• In terms of existing power infrastructure, Eco-Fuel use can transition fossil fuel power stations into renewable power stations simply by changing their fuel source whilst keeping the already established and costly infrastructure.

• Eco-Fuel products are made using state-of-the-art processing techniques that ensure high quality and consistent performance, this helps to assure reliability and consistency of the fuel source to the customer.

• With a designable calorific value, power companies that purchase Eco-Fuel require less product mass than coal per kilowatt to produce their products, resulting in a lower emissions output overall by the end user at a cost-effective benefit.

Eco-Fuel is a sustainable energy source that can be produced locally, which can help to:

• Create local jobs and support for communities

• Reduce the dependence on imported fossil fuels.

• Stimulate other circular economic growth in communities where it is produced.

• Can Create a new exportable commodity.

• Assists companies, governments and other authorities in achieving sustainability goals such as Zero-to-Landfill, Net-Zero and ESG targets alongside the adhering to multiple United Nations Sustainable Development Goals (UNSDGs).

• Can Enable base load renewable energy technology without intermittency or grid instability issues.

• Free up usable land taken up by landfills and increase their value whilst decreasing their waste and carbon footprint.

• Enables the repurposing of exiting landfill site (i.e. transforming all waste sites into valuable farming or building land).

Eco-Fuel is valuable for business or governments that wish to remove legacy landfill and utilise the area for other purposes.

The variety of materials able to be processed and used means that Eco-Fuel offers huge environmental benefits, resulting in reduced fossil fuel usage in coal-fired power plants, cement kilns, and pulp manufacturing plants (just to name a few). Conventional waste disposal can have serious environmental impacts including water pollution, methane and other GHG emissions and soil degradation (etc.). The production of Eco-Fuel will reduce the total landfill capacity and its overall land usage and environmental footprint.

• Materials sent to landfill such as non-recyclable plastics, food organics and wood materials (just to name a few) which would usually sit in landfill sites for periods spanning months, years, decades or hundreds of years before ever degrading, can instead be used in a helpful way to generate renewable heat and power by being repurposed into an Eco-Fuel feedstock. This in turn helps to reduce waste and pollution whilst preserving natural resources and recycling waste materials into a repurposed Eco-Fuel product to provide a clean, efficient and cost-effective energy source for commercial off-takers.

• Eco-Fuel helps to divert waste away from landfill and is a sustainable and environmentally friendly alternative to traditional fossil fuels; being used either as a fossil fuel partial substitute or complete replacement.

• In processing Eco-Fuel, incineration of landfill or municipal solid waste is not required. The landfill greenhouse gas emissions (GHGs) which would exist if landfill waste persisted is displaced, leading to minimal comparative embodied greenhouse gasses from the Eco-Fuel process and mitigate the effects of climate change.

• Eco-Fuel is a baseload renewable energy solution which allows for the storing and transportation of the fuel to be used without the issues of intermittency or power grid instability like many other renewable energy alternatives.

• With a designable calorific value, Eco-Fuel requires less mass than coal per kilowatt for power, resulting in a lower emissions output overall by the end user. Alternatively, a customer-specific lower calorific value can be designed to increase more Eco-Fuel throughput and get rid of more waste material.

• Using Eco-Fuel can help reduce the dependence on fossil fuels, which can help to mitigate the effects of air pollution, fossil fuel by-products and climate change.

• Emissions from Eco-Fuel in power systems can be mitigated with state-of-the-art air treatment technology to ensure minimal pollutants and adherence to environmental guidelines.

In processing ECO-FUEL, waste incineration is not required and the landfill gas emissions which would exist if landfill waste persisted is displaced; leading to minimal embodied greenhouse gas emissions (GHGs) in the ECO-FUEL production process. With a designable calorific value determined by customer specifications, power companies that purchase our product require less ECO-FUEL than coal per kilowatt-hour to produce their products, resulting in a lower emissions output overall by the end user and the transition of a non-renewable power station to a renewable power station.

Eco-Fuel is also valuable for entities that wish to remove legacy landfill and utilise the area for other purposes. The variety of materials able to be processed and used means that Eco-Fuel offers huge environmental benefits, resulting in reduced fossil fuel usage in coal-fired power plants, cement kilns, and pulp manufacturing plants (just to name a few).

Conventional waste disposal can have serious environmental impacts including water pollution, methane and other GHG emissions and soil degradation (etc.). The production of Eco-Fuel will reduce the total landfill capacity and its overall land usage and environmental footprint. Eco-Fuel can be produced and supplied at a design calorific value specified by the customer in coarse or fine shredded form, and compacted or baled for transport, depending on the end user’s requirement and location.

Overall, Eco-Fuel by Continuum Energy is a sustainable

solution that helps reduce waste and pollution, and provides a clean, efficient

and cost-effective energy source.

It can be used for wide variety of applications and helps to

create sustainable jobs and stimulate economic growth in communities where it

is produced. It enables companies and individuals to meet their sustainability

goals and reduce their carbon footprint.

Contact us now to find out more!